We Offer These Services

TUBE CUTTING SERVICES, FLAT SHEET LASER CUTTING SERVICES, WATERJET CUTTING SERVICES, & PRESS BRAKE SERVICES

Check out our new facility 788 W. Illini Phoenix AZ 85041

SWWJ Tube Cutting Services: The Faster, More Accurate, and Cost-Effective Solution to Your Tubing Needs

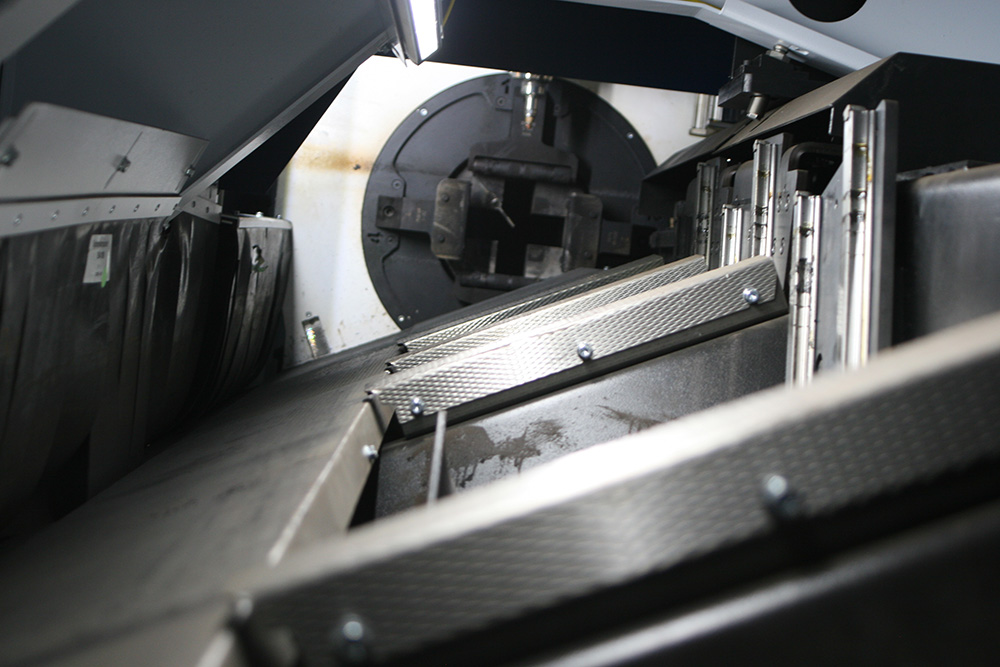

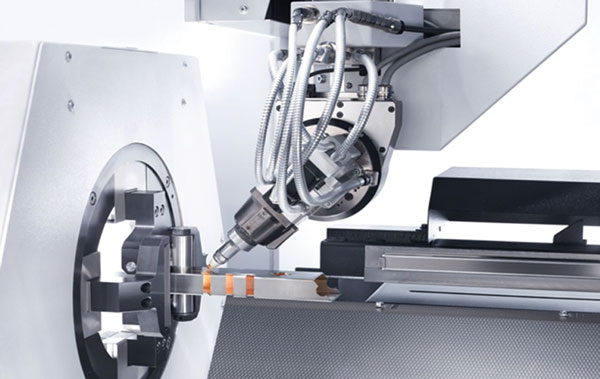

SWWJ can process tubes – faster than ever before. Our new TruLaser Tube 5000 fiber takes advantage of the strengths of solid-state lasers in a way that no other machine ever has done before.

The Need for Precise Tube Cutting in Various Industries

Tube cutting is an important task that is used across various industries, including construction, manufacturing, automotive, and plumbing. Industry growth has only increased the demand for tube cutting, which is the process that involves cutting tubes and profiles to specific lengths, shapes, and sizes, making them suitable for use in different applications. Tube cutting can be a challenging and time-consuming task, especially when dealing with heavy and thick materials. However, with the latest technology, tube cutting has become more efficient, accurate, and cost-effective than ever before.

For you as a customer, this means shorter processing times for a large range of possible tubes and profiles. Our new fiber optic tube processing machine is even more convincing: it is more efficient and can processes even heavier tubes and cuts through thicker materials thanks to increased laser power. See for yourself! This means added savings for our customers.

How SWWJ is Furthering our Tube Cutting Capabilities

Here Are Some Of The Highlights Of Our Tube Cutting Services

Significantly reduced part times – With Rapid Cut, the high feed rates of the solid-state laser come into their own even on smaller contours. This allows SWWJ to process tube quickly with outstanding precision!

Optimal access to the machine – Thanks to its open concept, the TruLaser Tube 5000 fiber offers optimum access.

Clamping without the need for retooling – With the clamping system of the TruLaser Tube 5000 fiber, tubes can be manufactured across the entire clamping range without the need for retooling.

Optimum cutting result – The TruDisk solid-state laser and high-quality cutting data produce the best possible results.

| Work Piece Weight | ||

|---|---|---|

| Maximum Weight | 25 kg/m | 16 lb/ft |

| Maximum Material Thickness | ||

| Mild Steel | 8mm | 0.31” |

| Stainless Steel | 5mm | 0.19″ |

| Aluminium | 6mm | 0.23″ |

| Copper | 4mm | 0.15″ |

| Brass | 4mm | 0.15″ |

Max Material Length

| Round Tube | ||

|---|---|---|

| Maximum outside diameter | 6.7″ | 170mm |

| Rectangular/Square Tube | ||

| Maximum Side Length | 6″/6.5″ | 152 mm/170mm |

| Max Input Length | 26″ | 8000mm |

| Max Output Length | 15″ | 6500mm |

• 21 TubeCapacity

• 45Deg.BevelCutting

• 6.7″RoundCapacity

• Cut,round,Square,Rect.

• Angle,C-Channel,Oval

High-quality bevel cuts – The bevel cutting option enables high-quality bevel cuts of up to 45°.

Excellent process reliability – The state-of-the-art sensor system ensures your entire machining process runs smoothly.

Speed – The traditional tube processing required multiple work centers just to cut the material. With our new high-speed fiber optic tube cutting center, we can now cut tubes faster and with higher precision than ever before. The cuts are typically very clean and do not require any secondary clean up.

Flexibility – SWWJ’s new fiber optic tube cutting center can process just about any tube, C- Channel, U-Channel, Angle Steel, Angle Aluminum, and many others.

Download A PDF For More Information On Tube Cutting