We Offer These Services

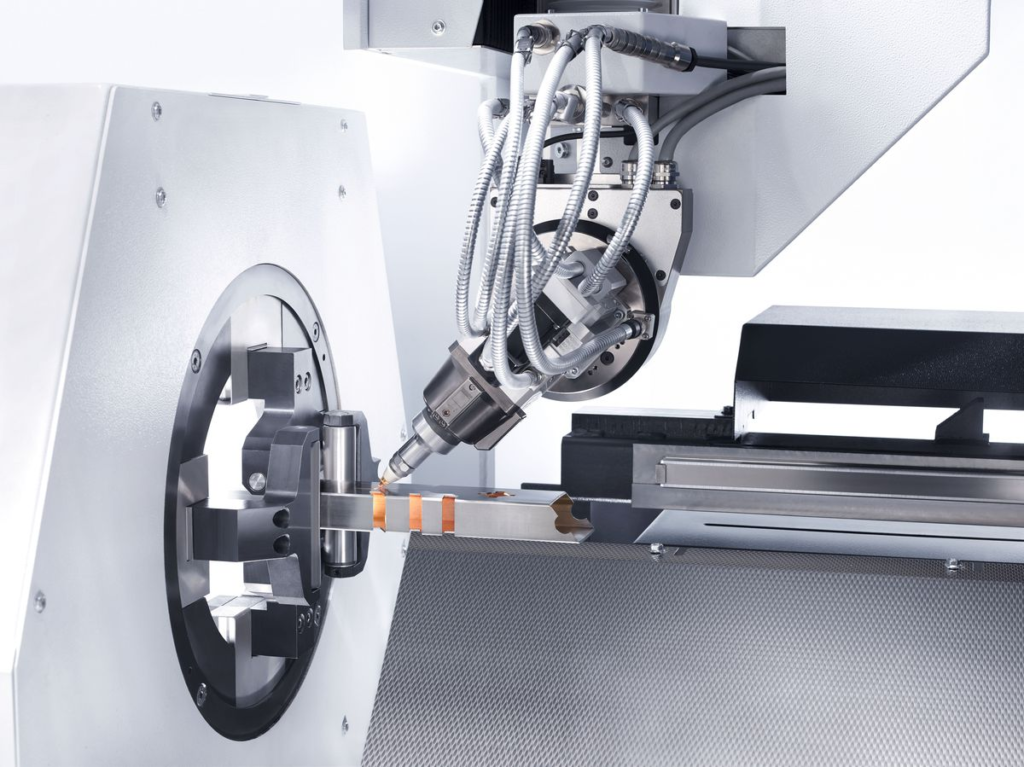

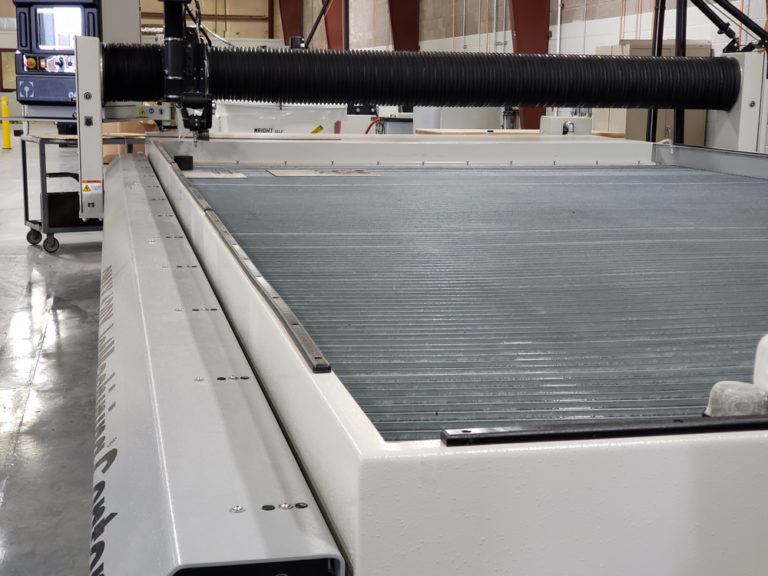

TUBE CUTTING SERVICES, FLAT SHEET LASER CUTTING SERVICES, WATERJET CUTTING SERVICES, & PRESS BRAKE SERVICES

Check out our new facility 788 W. Illini Phoenix AZ 85041

Laser Or WaterJet Services?

Choose The Right Technology For Your Application

Waterjets can cut thicker materials, up to 6″ thick and more.Low cost waterjet cutting in progress.

Lasers can usually cut thinner materials much faster and more cost effective.

Waterjets can cut virtually any material.

Lasers are more limited in what materials can or should be cut.

Waterjets are cut with very little Heat Affected Zone (HAZ).

Lasers heat material during the cutting process.

Waterjets can usually cut short run of parts at a lower cost. There is usually less setup time.

Lasers are better suited for long run of parts.

Waterjet tolerances can be programmed in a wide range, and a wide range of cut surface conditions.

Laser tolerances are about +/- .003, or better.

Waterjets can cut different material types with virtually no machine tooling changes.

Depending on material and job changes, setup time may vary between material and job changes.

Waterjets introduce water on the material surface.

Laser is dry cutting.

Waterjet can cut through different layers of material.

Lasers can only cut through one layer of material.

Contact Us Today To Get A Quote For a Quote email your .dxf, Solid Works, or AutoCAD, or other vector (.ai, .eps) file