What Are the Benefits of Tube Laser Cutting?

Are you looking to choose tube laser cutting services for your next fabrication project? In this article we will talk about why tube laser cutting is a great choice for your next project and some of the benefits of using tube laser cutting compared to other fabrication methods.

What is tube laser cutting?

How Is Tube laser Cutting Used?

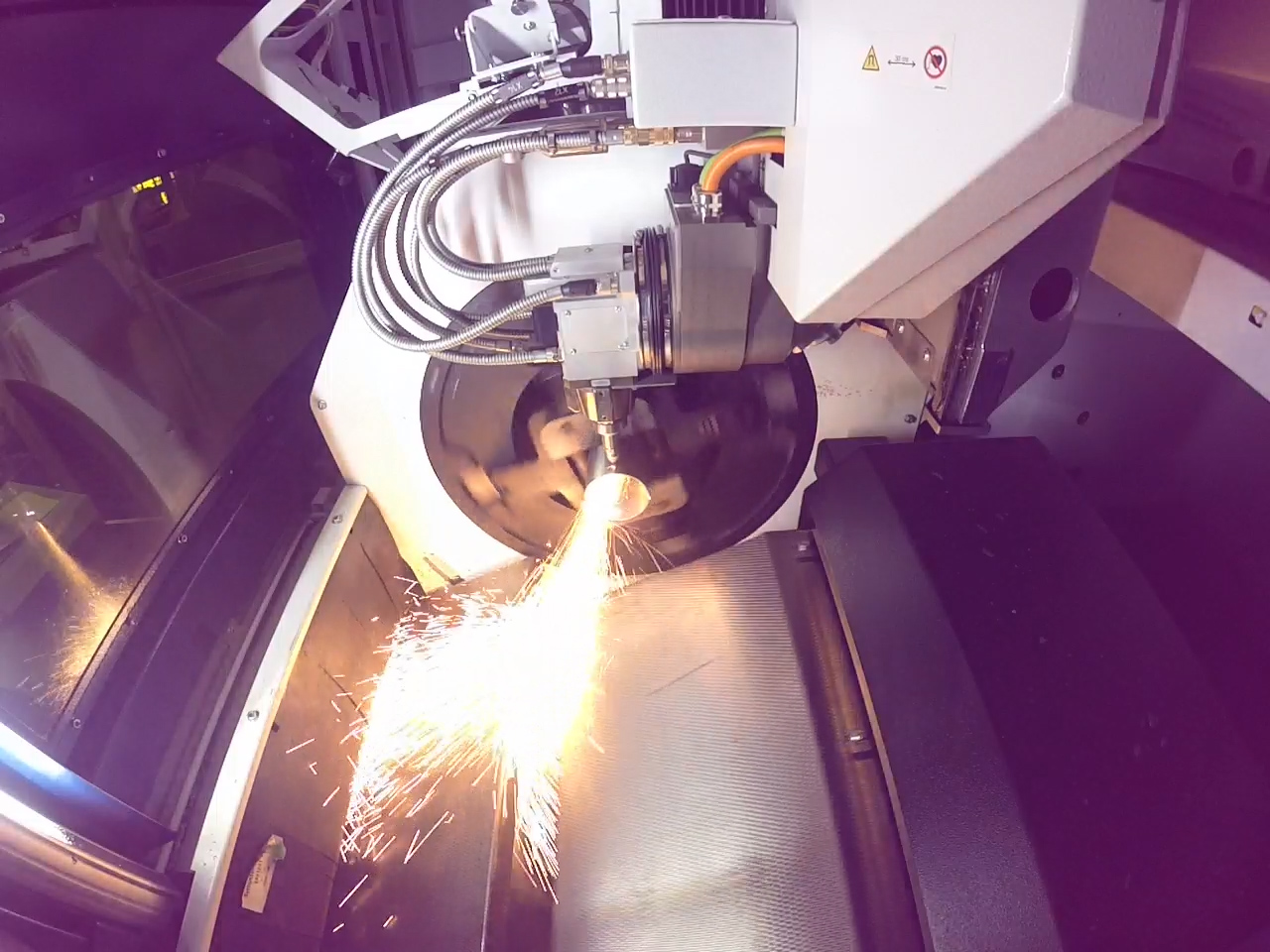

What Is Tube laser Cutting Equipment Like?

What Are The Benefits Of Tube laser Cutting?

What Is What is tube coping?

When to Use Tube laser Cutting Equipment?

What Are The Benefits Of Tube laser Cutting?

Why Opt For Tube laser Cutting Over Other Methods?

How Much Does Tube laser Cutting Cost?

What Is Tube laser Cutting?

Tube Laser cutting is a method of cutting materials using a laser. The laser beam is directed through a fiber optic cable and series of optics onto the material, which is then vaporized or melted by the heat of the laser.

How Is Tube laser Cutting Used?

Fabrication shops across the country rely on CNC laser cutting machines to cut metal. Laser tube cutting machines help fabricators achieve this by providing clean and consistent and very accurate precision cuts in a variety of materials.

Laser tube cutting is a specialty form of laser cutting that excels at cutting tubes, round, square, and rectangle shapes. It can also cut C-Channel, U-Channel and Angle

What Is Tube laser Cutting Equipment Like?

There are two major categories of tube laser cutting equipment: 2-axis and 3-axis. Both types are meant to handle varied cutting needs.

- 2-Axis Tube laser Cutting Equipment

The 2-axis tube laser cutting machines cut the tubes in 2 dimensions. Thus, this equipment type is used for cutting the material in length. Further, it is also used for features and joints to be deployed between tube pieces in different structures.

What Are The Benefits Of Tube laser Cutting?

- 3-Axis Tube laser Cutting Equipment

As the name suggests, a 3-axis tube laser cutter cuts the tubes in 3 dimensions. Hence, this equipment is best suited for tilt cutting, up to 45 degree angles. This can allow for very precise tube coping.

What is tube coping?

What is tube coping?

Tube Coping is joining the end of one piece of tubing to another is known as notching or coping It’s all based on angles that are determined by where you are placing the tube.

When to Use Tube laser Cutting Equipment?

This forms a valid question for manufacturing companies and business professionals. To put it simply, tube laser cutting is the best solution when:

- pieces of tubes are to be welded in a later stage of manufacturing

- very clean welding pieces are required

- tubes need bending prior to welding

- Precision and repeatability are required.

What Are The Benefits Of Tube laser Cutting?

If you’re looking for a more efficient and precise way to cut tube, channel or angle, you may want to consider the tube laser cutting process. This process uses a precision laser beam to cut through metal, and offers several benefits over traditional methods.

Tube laser cutting is faster and more accurate than other methods, which means less waste and fewer errors. It’s also cleaner than other methods.

One benefit of laser cutting tubes is that you don’t have to apply any force to the cut. The only thing holding the material together is the clamps. Normally, a CNC punch breaks through the material being cut with physical force. However, this stress on the surrounding material weakens it slightly. You can avoid this by using lasers instead of other cutting tools.

How Can Tube laser Cutting Enhance Your Business?

Why would a fabrication shop use a laser tube cutting machine? What are the benefits of providing this service?

Here are some of the ways that a laser tube cutting machine can benefit your business:

- Reducing Secondary Operations in Cutting Tubes

A physical blade used to cut a tube often leaves metal shavings and imperfections on the cut edge. These issues would need to be cleaned and polished before being used for whatever purpose it is intended for.

However, with a tube cutting machine, not only are the edges essentially flawless, but the slag from the cutting process can also be collected and kept out of the tube being cut. This means you don’t have to go through two processes: one to create clean cuts and another to keep the edges sharp.

A traditional laser cutting machine can create clean cuts but does not create the tube-shaped object you need. Using a tube cutting machine, you can simply cut a tube-shaped object directly.

- Stronger Tube Ends

One benefit of laser cutting tubes is that you don’t have to apply any force to the cut. The only thing holding the material together is the clamps. But if you put an elongated tube across the machine (about 12” or more), it will collapse from the gripper clamps. Normally, a CNC punch breaks through the material being cut with physical force. However, this stress on the surrounding material weakens it slightly. You can avoid this by using lasers instead of other cutting tools.

- Diversity of Cutting Processes

CNC machining is a type of advanced machining where machines move in precise patterns, allowing for many tasks to be performed by one machine. Laser tube cutting is no exception; instead of making vertical cuts, you can create angle cuts, slots, etchings, and more, depending on the equipment.

Traditional laser cutters are optimized for handling flat surfaces and cannot handle cylindrical objects well.

Why Opt For Tube laser Cutting Over Other Methods?

The answer to this question is simple, i.e., flexibility!

This technique of cutting is suited for various shapes, sizes, and materials of tubes.

Shapes

Tube laser cutting can efficiently handle tubes ranging from less than an inch up to 9 inches diameter, including tubes of round, rectangular, and even irregular profiles.

Sizes

Further, it works well for all lengths of the tubes, up to 26’. Thicknesses can be up to .375” thick.

Materials

Tube Laser cutting can be used on a wide range of materials. Metals commonly used with this cutting technique are carbon steel, stainless steel, aluminum, and titanium.

How Much Does Tube laser Cutting Cost?

Tube Laser cutting is a great way to save money on your tubing projects. It is a fast and efficient way to cut tubing, saving you a lot of money in the long run. There are many benefits to using a tube laser cutter, and we will explore some of them here.

Since tube laser cutting is a fast process, you can cut through a lot of material in a short amount of time, which can save you money on labor costs. Tube laser cutters are also very precise, so you can get perfect cuts every time.

Overall, tube laser cutting is a great way to save money on your next project. It is fast, precise, and versatile, and it can help you save money on labor and material.

Southwest Waterjet and Laser – Your Go-To For Tube laser Cutting Services.

Southwest Waterjet & Laser is a company that specializes in both waterjet and laser cutting services located in Phoenix, AZ, and offers our services in the whole of Phoenix. Our team has years of experience working with materials such as metal, plastic, rubber, wood, and glass. We use only state-of-the-art technology to ensure that your job is done right the first time without any damage to your valuable materials or equipment. We use a tube laser cutting machine to cut metal in Arizona and throughout the US. We make parts for the auto industry and other industries that use tubes of metal in their designs.

There are many benefits of tube laser cutting, from the precision of the cuts to the speed of the process. Tube laser cutting is a great option for anyone who needs high-quality, precise cuts on a variety of materials.

If you’re looking for a way to maximize your material usage and cut down on waste, look no further than Southwest Waterjet & Laser. We are now offering tube-cutting services in Arizona, and we’re excited to announce that our Trumpf Trulaser Tube 5000 is going to assist you and outperform any machine of its kind.

Not only does this precision and accuracy guarantee a perfect part every time, but it also boasts speeds that are up to 25 times faster than other machines, so you can get more done in less time. And with its efficiency, you won’t have to worry about wasting valuable material either—this machine can handle almost any job! Contact us today for more information about our laser cutting services or a quote on our tube cutting services.